Hyundai Genesis (DH): General Information / General Tightening Torque Table

General Information

| Tightening Torque Table of Standard Parts |

| BOLT (Nominal diameter) | NUT (Nominal diameter) | ||

|

|

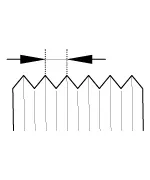

| BOLT/NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

Nominal diameter. (mm) | Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

| |

| M5 | 0.8 (0.031) | 2.0 ~ 3.0 (0.2 ~ 0.3, 1.4 ~ 2.2) | 4.9 ~ 6.9 (0.5 ~ 0.7, 3.6 ~ 5.1) | 7.8 ~ 10.8 (0.8 ~ 1.1, 5.8 ~ 8.0) |

| M6 | 1 (0.039) | 2.9 ~ 4.9 (0.3 ~ 0.5, 2.2 ~ 3.6) | 8.8 ~ 12.7 (0.9 ~ 1.3, 6.5 ~ 9.4) | 13.7 ~ 18.6 (1.4 ~ 1.9, 10.1 ~ 13.7) |

| M8 | 1.25 (0.049) | 8.8 ~ 11.8 (0.9 ~ 1.2, 6.5 ~ 8.7) | 22.6 ~ 30.4 (2.3 ~ 3.1, 16.6 ~ 22.4) | 33.3 ~ 44.1 (3.4 ~ 4.5, 24.6 ~ 32.5) |

| M10 | 1.5 (0.059) | 16.7 ~ 22.6 (1.7 ~ 2.3, 12.3 ~ 16.6) | 45.1 ~ 60.8 (4.6 ~ 6.2, 33.3 ~ 44.8) | 65.7 ~ 88.3 (6.7 ~ 9.0, 48.5 ~ 65.1) |

| M12 | 1.75 (0.068) | 29.4 ~ 39.2 (3.0 ~ 4.0, 21.7 ~ 28.9) | 78.5 ~ 105.9 (8.0 ~ 10.8, 57.9 ~ 78.1) | 114.7 ~ 154.9 (11.7 ~ 15.8, 84.6 ~ 114.3) |

| M14 | 2 (0.078) | 47.1 ~ 63.7 (4.8 ~ 6.5, 34.7 ~ 47.0) | 125.5 ~ 169.7 (12.8 ~ 17.3, 92.6 ~ 125.1) | 183.4 ~ 249.1 (18.7 ~ 25.4, 135.3 ~ 183.7) |

| M16 | 2 (0.078) | 73.5 ~ 100.0 (7.5 ~ 10.2, 54.2 ~ 73.8) | 197.1 ~ 266.7 (20.1 ~ 27.2, 145.4 ~ 196.7) | 288.3 ~ 390.3 (29.4 ~ 39.8, 212.7 ~ 287.9) |

| M20 | 2.5 (0.098) | 144.2 ~ 195.2 (14.7 ~ 19.9, 106.3 ~ 143.9) | 396.2 ~ 535.4 (40.4 ~ 54.6, 292.2 ~ 394.9) | 565.8 ~ 764.9 (57.7 ~ 78.0, 417.3 ~ 564.2) |

| M24 | 3 (0.118) | 249.1 ~ 337.3 (25.4 ~ 34.4, 183.7 ~ 248.8) | 687.4 ~ 929.7 (70.1 ~ 94.8, 507.0 ~ 685.7) | 975.8 ~ 1320.0 (99.5 ~ 134.6, 719.7 ~ 973.6) |

| M30 | 3.5 (0.137) | 499.2 ~ 674.7 (50.9 ~ 68.8, 368.2 ~ 497.6) | 1372.9 ~ 1858.4 (140.0 ~ 189.5, 1012.6 ~ 1370.7) | 1956.4 ~ 2647.8 (199.5 ~ 270.0, 1443.0 ~ 1952.9) |

| BOLT/NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

| Nominal diameter. (mm) | Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

| |

| M5 | 0.5 (0.019) | 2.0 ~ 3.0 (0.2 ~ 0.3, 1.4 ~ 2.2) | 5.9 ~ 8.8 (0.6 ~ 0.9, 4.3 ~ 6.5) | 8.8 ~ 12.7 (0.9 ~ 1.3, 6.5 ~ 9.4) |

| M6 | 0.75 (0.029) | 3.9 ~ 4.9 (0.4 ~ 0.5, 2.9 ~ 3.6) | 9.8 ~ 13.7 (1.0 ~ 1.4, 7.2 ~ 10.1) | 14.7 ~ 20.6 (1.5 ~ 2.1, 10.8 ~ 15.2) |

| M8 | 1 (0.039) | 8.8 ~ 11.8 (0.9 ~ 1.2, 6.5 ~ 8.7) | 24.5 ~ 32.4 (2.5 ~ 3.3, 18.1 ~ 23.9) | 35.3 ~ 48.1 (3.6 ~ 4.9, 26.0 ~ 35.4) |

| M10 | 1.25 (0.049) | 17.7 ~ 23.5 (1.8 ~ 2.4, 13.0 ~ 17.4) | 47.1 ~ 63.7 (4.8 ~ 6.5, 34.7 ~ 47.0) | 69.6 ~ 94.1 (7.1 ~ 9.6, 51.4 ~ 69.4) |

| M12 | 1.25 (0.049) | 32.4 ~ 44.1 (3.3 ~ 4.5, 23.9 ~ 32.5) | 86.3 ~ 117.7 (8.8 ~ 12.0, 63.7 ~ 86.8) | 127.5 ~ 172.6 (13.0 ~ 17.6, 94.0 ~ 127.3) |

| M14 | 1.5 (0.059) | 51.0 ~ 69.6 (5.2 ~ 7.1, 37.6 ~ 51.4) | 136.3 ~ 185.3 (13.9 ~ 18.9, 100.5 ~ 136.7) | 201.0 ~ 271.6 (20.5 ~ 27.7, 148.3 ~ 200.4) |

| M16 | 1.5 (0.059) | 79.4 ~ 107.9 (8.1 ~ 11.0, 58.6 ~ 79.6) | 211.8 ~ 286.4 (21.6 ~ 29.2, 156.2 ~ 211.2) | 311.8 ~ 421.7 (31.8 ~ 43.0, 230.0 ~ 311.0) |

| M20 | 1.5 (0.059) | 163.8 ~ 221.6 (16.7 ~ 22.6, 120.8 ~ 163.5) | 448.2 ~ 607.0 (45.7 ~ 61.9, 330.5 ~ 447.7) | 639.4 ~ 864.9 (65.2 ~ 88.2, 471.6 ~ 638.0) |

| M24 | 2 (0.078) | 276.5 ~ 373.6 (28.2 ~ 38.1, 204.0 ~ 275.6) | 759.0 ~ 1026.8 (77.4 ~ 104.7, 559.8 ~ 757.3) | 1080.7 ~ 1462.2 (110.2 ~ 149.1, 797.1 ~ 1078.4) |

| M30 | 2 (0.078) | 562.9 ~ 762.0 (57.4 ~ 77.7, 415.2 ~ 562.0) | 1553.4 ~ 2102.5 (158.4 ~ 214.4, 1145.7 ~ 1550.8) | 2210.4 ~ 2991.0 (225.4 ~ 305.0, 1630.3 ~ 2206.1) |

| Flange BOLT (Nominal diameter) | Flange NUT (Nominal diameter) | ||

|

|

| Flange BOLT/NUT Normal screw | Torque Nm (kg.m, Ib-ft) | |||

| Nominal diameter. (mm) | Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

| |

| M5 | 0.8 (0.031) | 2.0 ~ 2.9 (0.2 ~ 0.3, 1.4 ~ 2.2) | 5.9 ~ 7.8 (0.6 ~ 0.8, 4.3 ~ 5.8) | 8.8 ~ 11.8 (0.9 ~ 1.2, 6.5 ~ 8.7) |

| M6 | 1 (0.039) | 3.9 ~ 4.9 (0.4 ~ 0.5, 2.9 ~ 3.6) | 9.8 ~ 13.7 (1.0 ~ 1.4, 7.2 ~ 10.1) | 14.7 ~ 19.6 (1.5 ~ 2.0, 10.8 ~ 14.5) |

| M8 | 1.25 (0.049) | 8.8 ~ 11.8 (0.9 ~ 1.2, 6.5 ~ 8.7) | 24.5 ~ 32.4 (2.5 ~ 3.3, 18.1 ~ 23.9) | 35.3 ~ 48.1 (3.6 ~ 4.9, 26.0 ~ 35.4) |

| M10 | 1.5 (0.059) | 17.7 ~ 24.5 (1.8 ~ 2.5, 13.0 ~ 18.1) | 48.1 ~ 65.7 (4.9 ~ 6.7, 35.4 ~ 48.5) | 70.6 ~ 96.1 (7.2 ~ 9.8, 52.1 ~ 70.9) |

| M12 | 1.75 (0.068) | 31.4 ~ 43.1 (3.2 ~ 4.4, 23.1 ~ 31.8) | 84.3 ~ 113.8 (8.6 ~ 11.6, 62.2 ~ 83.9) | 123.6 ~ 167.7 (12.6 ~ 17.1, 91.1 ~ 123.7) |

| M14 | 2 (0.078) | 51.0 ~ 68.6 (5.2 ~ 7.0, 37.6 ~ 50.6) | 135.3 ~ 182.4 (13.8 ~ 18.6, 99.8 ~ 134.5) | 198.1 ~ 268.7 (20.2 ~ 27.4, 146.1 ~ 198.2) |

| M16 | 2 (0.078) | 79.4 ~ 107.9 (8.1 ~ 11.0, 58.6 ~ 79.6) | 212.8 ~ 288.3 (21.7 ~ 29.4, 157.0 ~ 212.7) | 311.8 ~ 421.7 (31.8 ~ 43.0, 230.0 ~ 311.0) |

| Flange BOLT/NUT Thin screw | Torque Nm (kg.m, Ib-ft) | |||

Nominal diameter. (mm) | Pitch [mm (in.) ] | 4T | 8T | 10T |

|

|

|

| |

| M5 | 0.5 (0.019) | 2.9 ~ 2.9 (0.3 ~ 0.3, 2.2 ~ 2.2) | 6.9 ~ 8.8 (0.7 ~ 0.9, 5.1 ~ 6.5) | 9.8 ~ 13.7 (1.0 ~ 1.4, 7.2 ~ 10.1) |

| M6 | 0.75 (0.029) | 3.9 ~ 5.9 (0.4 ~ 0.6, 2.9 ~ 4.3) | 10.8 ~ 14.7 (1.1 ~ 1.5, 8.0 ~ 10.8) | 16.7 ~ 21.6 (1.7 ~ 2.2, 12.3 ~ 15.9) |

| M8 | 1 (0.039) | 9.8 ~ 12.7 (1.0 ~ 1.3, 7.2 ~ 9.4) | 26.5 ~ 35.3 (2.7 ~ 3.6, 19.5 ~ 26.0) | 38.2 ~ 52.0 (3.9 ~ 5.3, 28.2 ~ 38.3) |

| M10 | 1.25 (0.049) | 19.6 ~ 25.5 (2.0 ~ 2.6, 14.5 ~ 18.8) | 51.0 ~ 68.6 (5.2 ~ 7.0, 37.6 ~ 50.6) | 75.5 ~ 102.0 (7.7 ~ 10.4, 55.7 ~ 75.2) |

| M12 | 1.25 (0.049) | 35.3 ~ 48.1 (3.6 ~ 4.9, 26.0 ~ 35.4) | 94.1 ~ 126.5 (9.6 ~ 12.9, 69.4 ~ 93.3) | 138.3 ~ 186.3 (14.1 ~ 19.0, 102.0 ~ 137.4) |

| M14 | 1.5 (0.059) | 55.9 ~ 75.5 (5.7 ~ 7.7, 41.2 ~ 55.7) | 148.1 ~ 200.1 (15.1 ~ 20.4, 109.2 ~ 147.6) | 216.7 ~ 293.2 (22.1 ~ 29.9, 159.8 ~ 216.3) |

| M16 | 1.5 (0.059) | 86.3 ~ 116.7 (8.8 ~ 11.9, 63.7 ~ 86.1) | 229.5 ~ 309.9 (23.4 ~ 31.6, 169.3 ~ 228.6) | 336.4 ~ 455.0 (34.3 ~ 46.4, 248.1 ~ 335.6) |

General Information Towing If the vehicle needs to be towed, call a professional towing service. It is very dangerous to tow a vehicle with just a rope or chain. General Information Basic Service Symbols There are five primary symbols used to complement illustrations. These symbols indicated the materials to be applied to parts during service. Other information:Hyundai Genesis (DH) 2013-2016 Service Manual: Auto Head Lamp Leveling Unit Description and OperationDescription According to driving environment and loading state of vehicle, head lamp lighting direction is changed to keep the driver's visibility range and to protect the driver's vision from glare, aiming at safety driving. Sensor integrated ECU mounting on the rear center arm drives the actuator mounting on the head lamp since sens Hyundai Genesis (DH) 2013-2016 Service Manual: Blind Spot Detection Indicator Repair proceduresRemoval Blind Spot Detection Warning Indicator 1. Disconnect the negative (-) battery terminal. 2. Remove the mirror (A). Installation Blind Spot Detection Warning Indicator 1. Install the outside mirror. 2. Connect the negative (-) battery terminal. Categories

Copyright В© 2026 www.hgenesisdh.com - 0.0312

|