Hyundai Genesis (DH): Blind Spot Detection system / Repair procedures

Hyundai Genesis (DH) 2013-2016 Service Manual / Body Electrical System / Blind Spot Detection system / Repair procedures

| Diagnosis With GDS |

| 1. |

BSD system defects can be quickly diagnosed with the GDS. GDS

operates actuator quickly to monitor, input/output value and self

diagnosis. |

| 2. |

Connect the cable of GDS to the data link connector in driver side crash pad lower panel, and turn on the GDS. |

| 3. |

Select the vehicle model and then BSD system. |

| 4. |

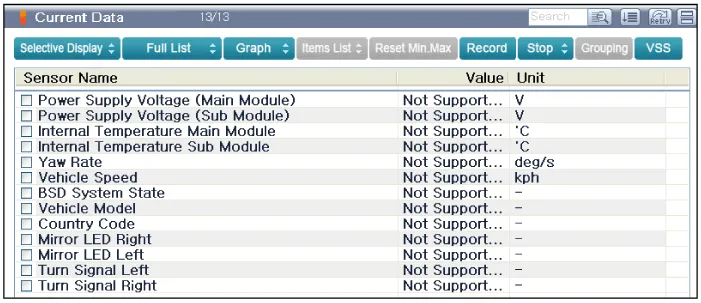

Select "Input/output monitoring", if you want to check current data of BSD system.

|

| 5. |

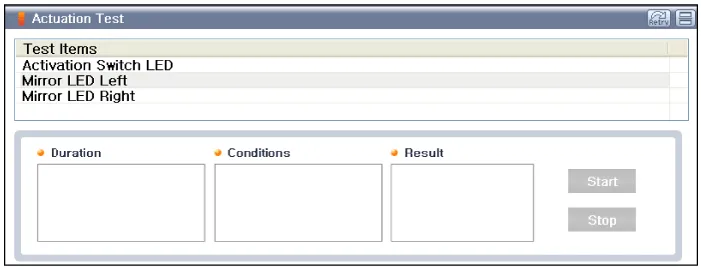

If you want to check each module operation forcefully, select "Actuation test".

|

Description BSD is a system that measures the speed of and distance from the following vehicles by using two magnetic wave radar sensors attached to the rear bumper, and detects any vehicle within the blind spot zone and gives off alarm (visual and auditory).

Circuit Diagram

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: Specifications

S

Hyundai Genesis (DH) 2013-2016 Service Manual: Ambient Temperature Sensor Description and Operation

Description The ambient temperature sensor is located inside the side mirror and detects ambient air temperature. It is a negative type thermistor; resistance will increase with lower temperature, and decrease with higher temperature. The sensor output will be used for discharge temperature control, temperature regulation door control,

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- 4 Wheel Drive (AWD) System

- Electric Parking Brake (EPB) Repair procedures

- Body Electrical System

- New on site

- Most important about car

Copyright В© 2026 www.hgenesisdh.com - 0.0261