Hyundai Genesis (DH): Timing System / Drive Belt Repair procedures

| Removal and Installation |

| 1. |

Disconnect the battery "-" terminal from the trunk room. |

| 2. |

Remove the engine cover.

(Refer to Engine And Transaxle Assembly - "Engine Cover") |

| 3. |

Remove the engine room cover.

(Refer to Engine And Transaxle Assembly - "Engine Cover") |

| 4. |

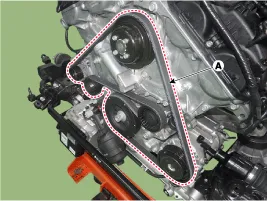

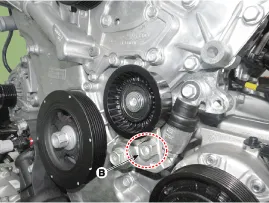

Turn the tensioner (B) clockwise and loosen it, then remove the drive belt (A).

|

| 5. |

To install, reverse the removal procedure. |

| Inspection |

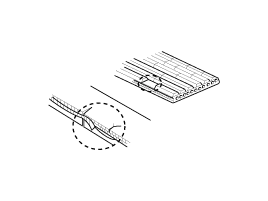

Cracks on the rib side of a belt are considered acceptable.

If the belt has chunks missing from the ribs, it should be

replaced. |

| 1. |

Check the idler for excessive oil leakage, abnormal rotation or vibration. Replace the idler if necessary. |

| 2. |

Check the belt tensioner for excessive dust, crack, and damage and inspect it Replace if necessary. |

| 3. |

Check the belt replacement cycle, and inspect the belt for the abnormal wear of v-ripped part and uneven wear if necessary. |

| 4. |

Check the crankshaft pulley, auxiliary pulley for vibration

when rotating, and V-ribbed part for foreign materials or uneven

contact. Replace the components if necessary. |

Components 1. Drive belt2. Drive belt tensioner3. Crankshaft pulley4. Water pump pulley5. Idler6. Cylinder head cover7. Exhaust camshaft OCV cap 1.

Components 1. Idler

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: General Safety Information and Caution

Instructions When Handling Refrigerant 1. R-134a liquid refrigerant is highly volatile. A drop on the skin of your hand could result in localized frostbite. When handling the refrigerant, be sure to wear gloves. 2. It is standard practice to wear goggles or glasses to protect your eyes, and gloves to protect your hands.

Hyundai Genesis (DH) 2013-2016 Service Manual: Cluster Ionizer Repair procedures

Inspection 1. Press the MODE switch more than 4 times within 2 seconds while pressing the OFF switch. DisplayFail description00Normal51Cluster ion generator fault * For diagnostic procedure, refer to DTC guide. Replacement 1. Disconnect the negative (-) battery terminal.

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- 4 Wheel Drive (AWD) System

- Engine Coolant Temperature Sensor (ECTS) Repair procedures

- Brake System

- New on site

- Most important about car