Hyundai Genesis (DH): Motor Driven Power Steering / Steering Gear box Repair procedures

Hyundai Genesis (DH) 2013-2016 Service Manual / Steering System / Motor Driven Power Steering / Steering Gear box Repair procedures

| Replacement |

| [LHD] |

| 1. |

Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. |

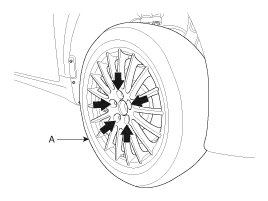

Remove the front wheel and tire (A) from the front hub.

|

| 3. |

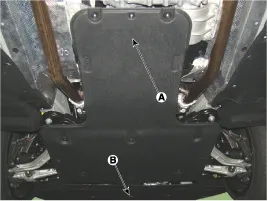

Remove the under cover (A), (B).

|

| 4. |

Remove the tie rod end ball joint from the knuckle.

|

| 5. |

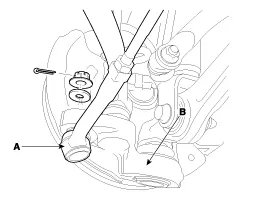

Unscrew the steering column bolt (A) to disconnect the universal joint and steering gear connection.

|

| 6. |

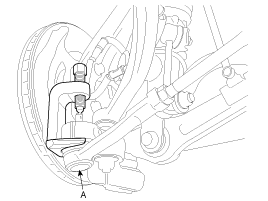

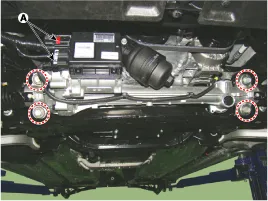

Disconnect the connector (A) and then loosen the gear box mounting bolts.

[4WD]

[2WD]

|

| [RHD] |

| 1. |

Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. |

Remove the front wheel and tire (A) from the front hub.

|

| 3. |

Remove the under cover (A), (B).

|

| 4. |

Remove the tie rod end ball joint from the knuckle.

|

| 5. |

Unscrew the steering column bolt (A) to disconnect the universal joint and steering gear connection.

|

| 6. |

Disconnect the connector (A).

|

| 7. |

Loosen the gear box mounting bolts.

|

| Installation |

| 1. |

Install in the reverse order of removal. |

| 2. |

Check the alignment.

(Refer to Suspension System - "Alignment") |

EPS Specification Recognition

Precautions when performing the EPS specification recognition procedure:

| |

Components Location [4WD] 1. Steering gear box2. Motor3. ECU4. Sub frame5. Knuckle [2WD] 1. Steering gear box2. Motor3. ECU4. Sub frame

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: Auto Head Lamp Leveling Unit Troubleshooting

Inspection with GDS Initialization and diagnosis sequence by using GDS equipment. The following is the summarized A/S procedure. NoProcedure1Park the vehicle on level ground2Tire check3IGN1 ON4Head lamp Low Beam ON5Connection with diagnostic tool6Initial command by diagnostic tool7Clear DTC Code8IGN1 OFF > ON9Re- Connection with diagnostic t

Hyundai Genesis (DH) 2013-2016 Service Manual: In-car Sensor Repair procedures

I

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Engine Coolant Temperature Sensor (ECTS) Repair procedures

- Rain Sensor Repair procedures

- 4 Wheel Drive (AWD) System

- New on site

- Most important about car

Copyright В© 2026 www.hgenesisdh.com - 0.0529