Hyundai Genesis (DH): Starting System / Starter Repair procedures

| Removal |

| 1. |

Turn ignition switch OFF and disconnect the negative (-) battery cable. |

| 2. |

Remove the RH engine manifold.

(Refer to Engine Mechanical System - "Exhaust Manifold") |

| 3. |

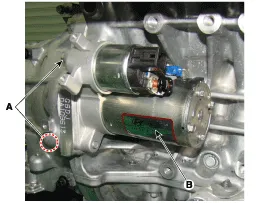

Remove the engine support bracket (A) after loosening the install bolt and nut.

|

| 4. |

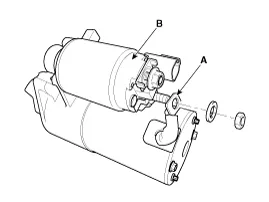

Disconnect the starter connector (A) and cable (B) from the 'B' terminal.

|

| 5. |

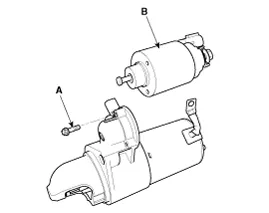

Remove the starter (B) after removing the mounting bolts (A).

|

| Installation |

| 1. |

Install in the reverse order of removal.

|

| Disassembly |

| 1. |

Disconnect the M-terminal from the magnet switch assembly.

|

| 2. |

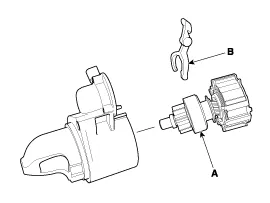

After loosening the 3 screws (A), detach the magnet switch assembly (B).

|

| 3. |

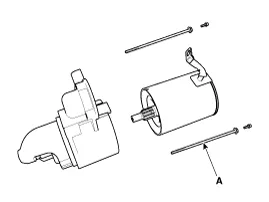

Loosen the through bolts (A).

|

| 4. |

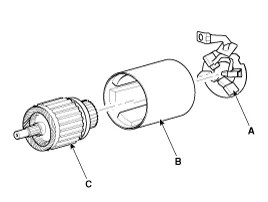

Remove the brush holder assembly (A), yoke (B) and armature (C).

|

| 5. |

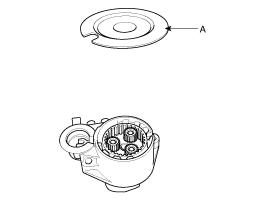

Remove the shield (A).

|

| 6. |

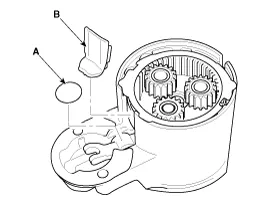

Remove the lever plate (A) and lever packing (B).

|

| 7. |

Disconnect the planet gear (A).

|

| 8. |

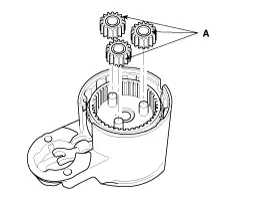

Disconnect the planet shaft assembly (A) and lever (B).

|

| 9. |

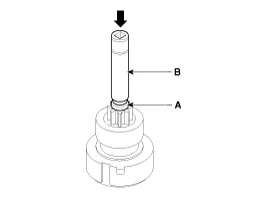

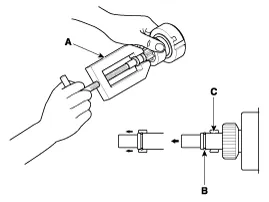

Press the stop ring (A) using a socket (B).

|

| 10. |

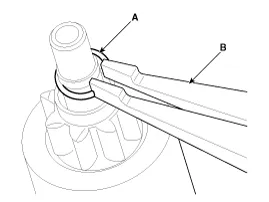

Remove the stopper (A) using the stopper pliers (B).

|

| 11. |

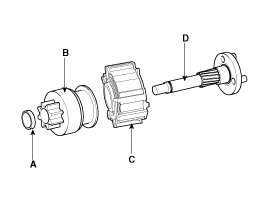

Disconnect the stop ring (A), overrunning clutch (B), internal gear (C) and planet shaft (D).

|

| 12. |

To reassemble, reverse the order of disassembly.

|

| Inspection |

| 1. |

Disconnect the lead wire from the M-terminal of solenoid switch. |

| 2. |

Connect the battery as shown. If the starter pinion pops out, it is working properly.

|