Hyundai Genesis (DH): Engine Control System / Oil Pressure Sensor (OPS) Description and Operation

| Description |

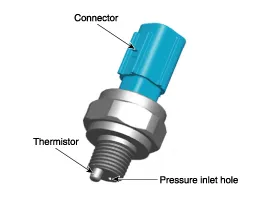

Inspection 1. Turn the ignition switch OFF. 2. Disconnect the OTS connector. 3. Remove the OTS (Refer to "Removal"). 4. After immersing the thermistor of the sensor into engine coolant, measure resistance between the OTS terminals 1 and 2.

Specifications TerminalResistance (k?)2 - 42.76 ~ 4.132 - 31.89 ~ 2.843 - 41.71 ~ 2.84

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: Compressor Description and Operation

Description The compressor is the power unit of the A/C system. It is located on the side of engine block and driven by a V-belt of the engine. The compressor changes low-pressure and low-temperature refrigerant gas into high-pressure and high-temperature refrigerant gas.

Hyundai Genesis (DH) 2013-2016 Service Manual: Compressor Repair procedures

Removal 1. If the compressor is marginally operable, run the engine at idle speed, and let the air conditioning work for a few minutes, then shut the engine off. 2. Disconnect the negative (-) battery terminal. 3. Remove the engine room cover.

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Electric Parking Brake (EPB) Repair procedures

- ECS-G Sensor Repair procedures

- Body Electrical System

- New on site

- Most important about car