Hyundai Genesis (DH): General Information / Special Service Tools

Hyundai Genesis (DH) 2013-2016 Service Manual / Engine Mechanical System / General Information / Special Service Tools

| Special Service Tools |

| Tool Name / Number | Illustration | Description |

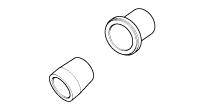

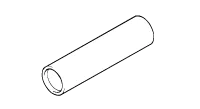

| Crankshaft front oil seal installer 09231-3C100 |

| Front oil seal mounting |

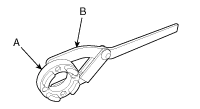

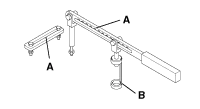

| Crankshaft pulley fixing tool (09231-1S100) Crankshaft pulley fixed tool handle (09231-2J210) |

| Remove the crankshaft damper pulley and mounting bolts A : 09231-1S100 B : 09231-2J210 |

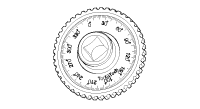

| Torque angle adapter 09221-4A000 |

| Used for tightening torque-to-yield fasteners to a specified angle |

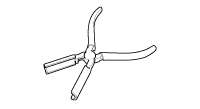

| Valve stem seal remover 09222-29000 |

| |

| Valve stem seal installer 09222-2W100 |

| Mounting of the valve stem seals |

| Valve spring compressor A : 09222-3K000 (Compressor) B : 09222-3K100 (Holder) |

| Used for removing / installing intake or exhaust valve |

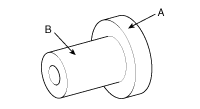

| Crankshaft rear oil seal installer A : 09231-3C200 B : 09231-H1100 |

| Mounting of the crankshaft rear oil seal |

| Oil pan remover 09215-3C000 |

| Remove the oil pan |

Troubleshooting SymptomSuspect areaRemedyEngine misfire with abnormal internal lower engine noises.Oil short or oil plethora bearing wearLoose or damaged engine drive plate.

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Engine Coolant Temperature Sensor (ECTS) Repair procedures

- Steering System

- Suspension System

- New on site

- Most important about car

Copyright В© 2026 www.hgenesisdh.com - 0.037