Hyundai Genesis (DH): Body Dimensions / General Information

Hyundai Genesis (DH) 2013-2016 Service Manual / Body (Interior and Exterior) / Body Dimensions / General Information

| General |

| 1. |

Basically, all measurements in this manual are taken with a tracking gauge. |

| 2. |

When a measuring tape is used, check to be sure there is no elongation, twisting or bending. |

| 3. |

For measuring dimensions, both projected dimension and actual-measurement dimension are used in this manual. |

| Measurement Method |

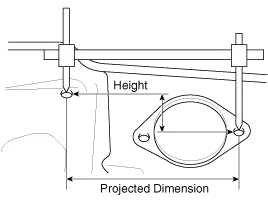

| Projected Dimensions |

| 1. |

These are the dimensions measured when the measurement

points are projected into the reference plane, and are the reference

dimensions used for body alterations. |

| 2. |

If the length of the tracking gauge probes is adjustable,

make the measurement by lengthening one probe by the amount equivalent

to the difference in height of the two surfaces.

|

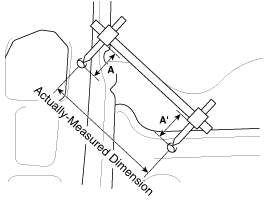

| Actual-Measurement Dimensions |

| 1. |

These dimensions indicate the actual linear distance between

measurement points, and are the reference dimensions for use if a

tracking gauge is used for measurement. |

| 2. |

Measure by first adjusting both probes to the same length (A=A').

|

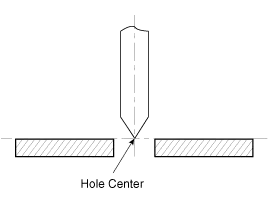

| Measurement Point |

| 1. |

Measurements should be taken at the hole center.

|

Front Body A * These dimensions indicated in this figure are actual-measurement dimensions. [ Unit : mm (inch) ] Front Body B * These dimensions indicated in this figure are actual-measurement dimensions.

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: Head Up Display Unit Repair procedures

Removal 1. Disconnect the negative (-) battery terminal. 2. Remove the head up display bezel (A). 3. Remove the instrument cluster. (Refer to Indicators And Guages - "Instrument Cluster") 4. Remove the head up display unit bracket (A) after loosening the mounting nuts.

Hyundai Genesis (DH) 2013-2016 Service Manual: Troubleshooting

Troubleshooting Problem Symptoms Table Before replacing or repairing air conditioning components, first determine if the malfunction is due to the refrigerant charge, air flow or compressor. Use the table below to help you find the cause of the problem.

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Body Electrical System

- Body (Interior and Exterior)

- Electric Parking Brake (EPB) Repair procedures

- New on site

- Most important about car

Copyright В© 2026 www.hgenesisdh.com - 0.0335