Hyundai Genesis (DH): General Information / Description and Operation

| Description |

| 1. |

Description

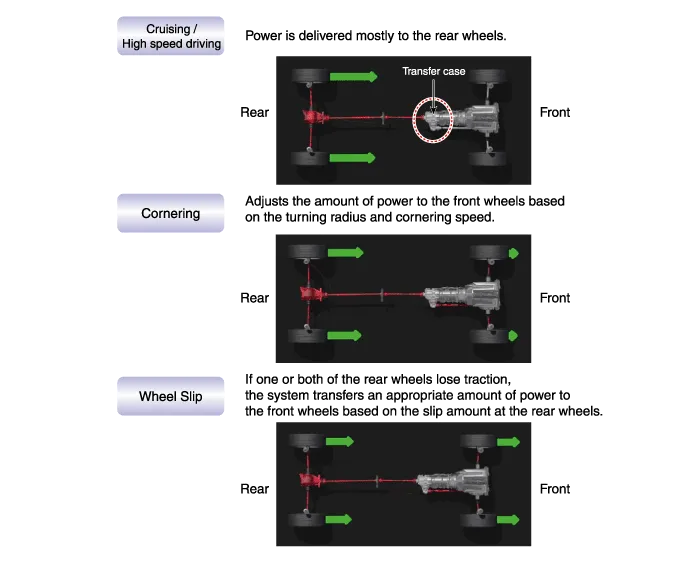

Distribution of electronically controlled driving force Distribution of electronically controlled driving force

Mutual controlling with the related driving control system Mutual controlling with the related driving control system

|

| 2. |

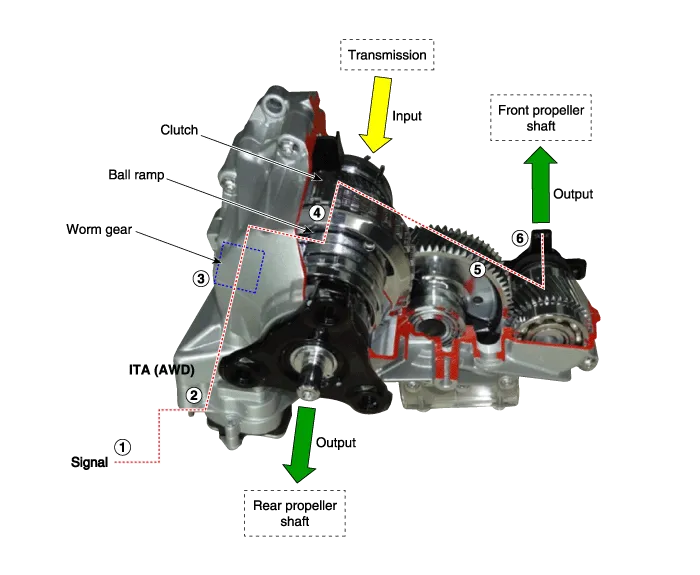

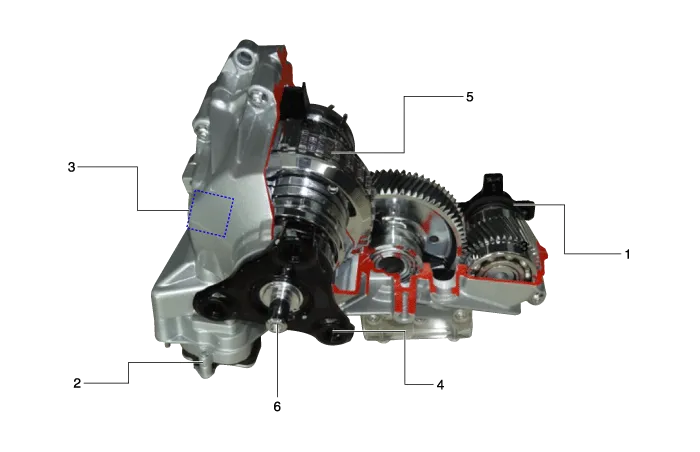

Structure of transfer case

|

| 3. |

Outline of driving force distribution

|

| 4. |

Transfer case operation

1) Transfer case operation procedure

? ITA (Integrated Transfer case Actuator)

|

Specification ItemSpecificationProduct nameTransfer caseOperation methodElectronic actuator control method (BLDC motor)Torque capacity1,100 NmWeight25 kg (Oil injection state) Tightening Torques Item N.

Adjustment Introduction It is necessary to check and input the calibration data when the controller is replaced as the characteristics of the internal frictional materials (clutch pack) change due to driving.

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: Receiver-Drier Repair procedures

Replacement 1. Remove the condenser. 2. Remove the cap (B) on the bottom of the condenser with the L wrench (A). Tightening torque : 9.81 ~ 14.71 N.m (1.0 ~ 1.5 kgf.m, 7.2 ~ 10.8 lb-ft) 3. Remove the receiver-drier (A) from condenser using a long nose plier.

Hyundai Genesis (DH) 2013-2016 Service Manual: Console Temperature Control Actuator Repair procedures

Inspection 1. Turn the ignition switch OFF. 2. Disconnect the console temperature control actuator connector. 3. Verify that the console temperature control actuator operates to the defrost mode when connecting 12V to terminal 3 and grounding terminal 4.

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Driveshaft and axle

- Electric Parking Brake (EPB) Repair procedures

- Emission Control System

- New on site

- Most important about car

Operation of Ball ramp with worm gear

Operation of Ball ramp with worm gear Clutch operation with Ball ramp operation

Clutch operation with Ball ramp operation Transmitting of torque to the gear with clutch operation

Transmitting of torque to the gear with clutch operation Applying the driving force to the front wheel

Applying the driving force to the front wheel