Hyundai Genesis (DH): General Information / Troubleshooting

| Basic Troubleshooting |

Special Service Tools ItemIllustrationApplicationFuel Pressure Gauge(09353-24100)Measuring the fuel line pressureFuel Pressure Gauge Adapter(09353-02100)Connection between the high pressure fuel pump and the fuel feed lineHeated Oxygen Sensor Socket Wrench(09392-1Y100)Removal and installation of the heated oxygen sensor? SST No.

Other information:

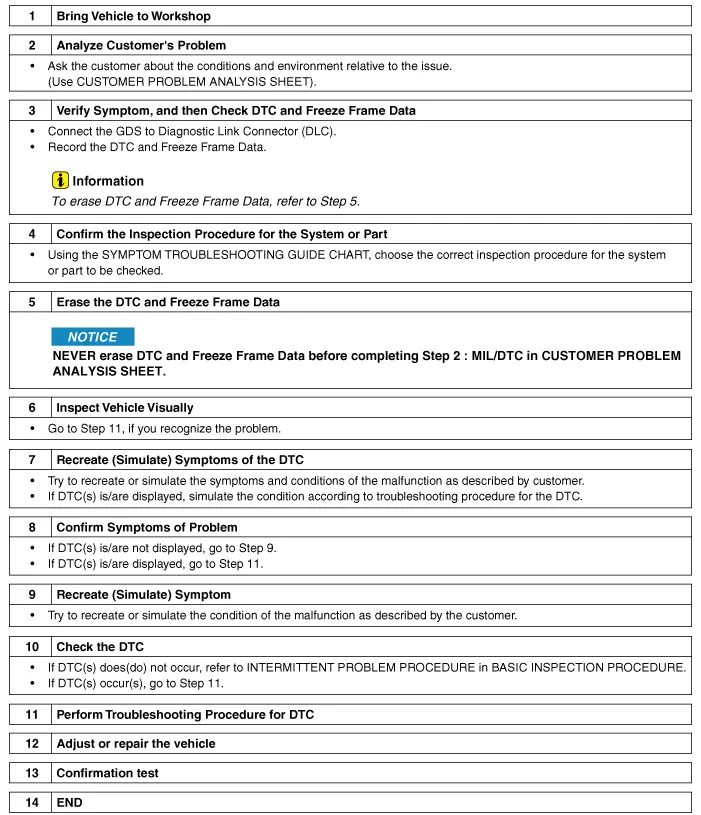

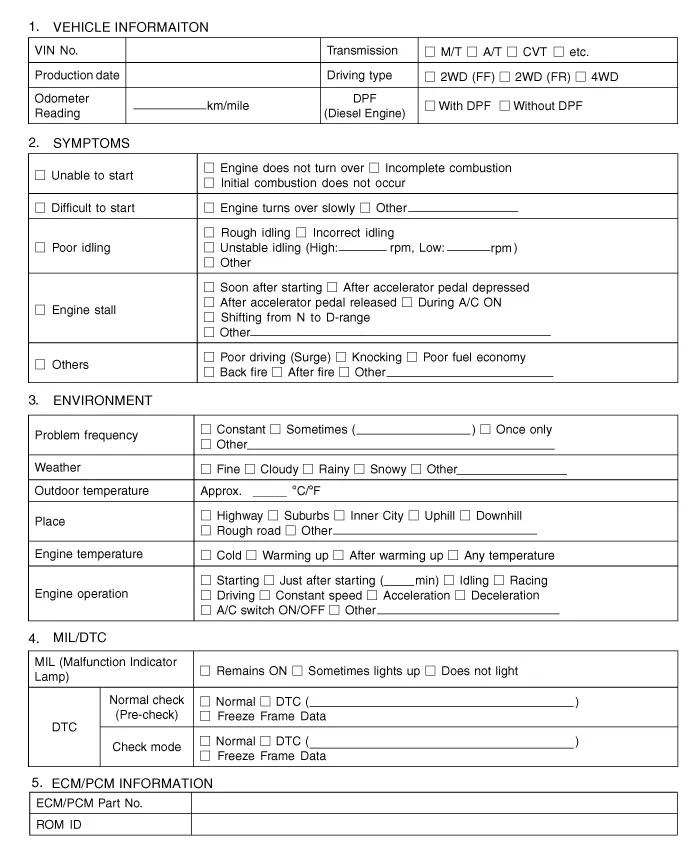

Hyundai Genesis (DH) 2013-2016 Service Manual: Troubleshooting

Troubleshooting Problem Symptoms Table Before replacing or repairing air conditioning components, first determine if the malfunction is due to the refrigerant charge, air flow or compressor. Use the table below to help you find the cause of the problem.

Hyundai Genesis (DH) 2013-2016 Service Manual: Auto Defogging Actuator Description and Operation

Description The auto defogging sensor is installed on front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives a signal from the sensor and restrains moisture and eliminates defog by the intake actuator, A/C, auto defogging actuator, blower motor

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Automatic Transmission System (SBC)

- General Information

- Engine Control / Fuel System

- New on site

- Most important about car