Hyundai Genesis (DH): Fuses And Relays / Relay Box (Engine Compartment) Repair procedures

Hyundai Genesis (DH) 2013-2016 Service Manual / Body Electrical System / Fuses And Relays / Relay Box (Engine Compartment) Repair procedures

| Inspection |

| 1. |

Disconnect the negative (-) battery terminal. |

| 2. |

Pull out the relay from the engine compartment relay box. |

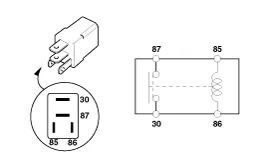

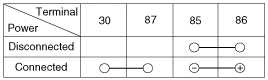

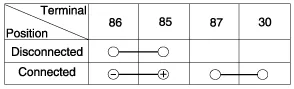

Power Relay (Type A)

Check for continuity between the terminals.

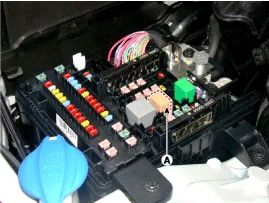

A : start relay

| 1. |

After supplying power to between No. 85 and 86 power relay

terminals, check that there is continuity between No. 30 and 87

terminals. |

| 2. |

After disconnecting power between No. 85 and 86 power relay

terminals, check that there is no continuity between No. 30 and 87

terminals.

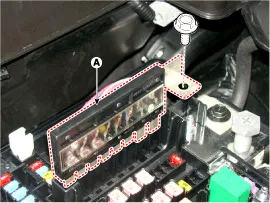

Engine Room Relay Box

Diesel Box

|

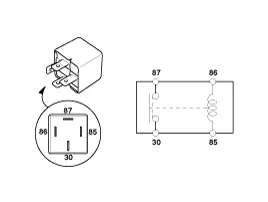

Power Relay (Type B)

Check for continuity between the terminals.

A : Cooling fan relay

| 1. |

After supplying power to between No. 85 and 86 power relay

terminals, check that there is continuity between No. 30 and 87

terminals. |

| 2. |

After disconnecting power between No. 85 and 86 power relay

terminals, check that there is no continuity between No. 30 and 87

terminals.

|

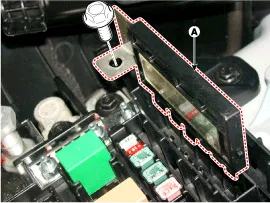

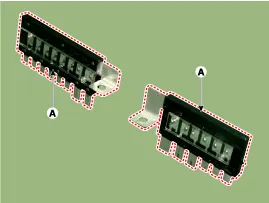

Metal Core PCB block

| 1. |

Disconnect the battery(-) terminals. |

| 2. |

Push the four hooks in the direction of the arrow and lift up the metal core PCB block (A).

|

| 3. |

Remove the metal core PCB by disconnecting the connector. |

Fuse

| 1. |

Check that the fuse holders are loosely held and that the fuses are securely fixed by the holders. |

| 2. |

Check that each fuse circuit has the exact fuse capacity. |

| 3. |

Check the fuses for any damage.

|

Multi Fuse

Engine room fuse is to optimize the package.

|

Component Location Engine room junction block Battery junction block

Component Location Interior Junction Block

Other information:

Hyundai Genesis (DH) 2013-2016 Service Manual: Components and Components Location

C

Hyundai Genesis (DH) 2013-2016 Service Manual: Auto Head Lamp Leveling Unit Troubleshooting

Inspection with GDS Initialization and diagnosis sequence by using GDS equipment. The following is the summarized A/S procedure. NoProcedure1Park the vehicle on level ground2Tire check3IGN1 ON4Head lamp Low Beam ON5Connection with diagnostic tool6Initial command by diagnostic tool7Clear DTC Code8IGN1 OFF > ON9Re- Connection with diagnostic t

Categories

- Manuals Home

- Hyundai Genesis Owners Manual

- Hyundai Genesis Service Manual

- Heating, Ventilation and Air Conditioning

- Front Door

- Restraint

- New on site

- Most important about car

Copyright В© 2026 www.hgenesisdh.com - 0.0201