Hyundai Genesis (DH): Front Suspension System / Front Strut Assembly Repair procedures

| Removal |

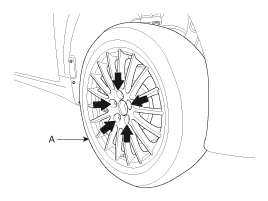

| 1. |

Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. |

Remove the front wheel and tire (A) from the front hub.

|

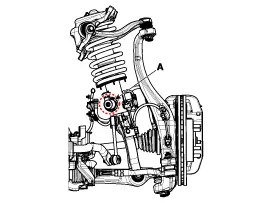

| 3. |

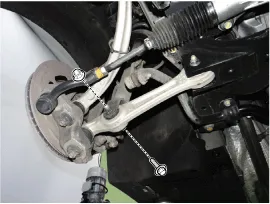

Using a hex wrench, fix the end of stabilizer link and then loosen the nut(A).

[ECS]

[HPD]

|

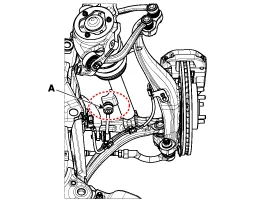

| 4. |

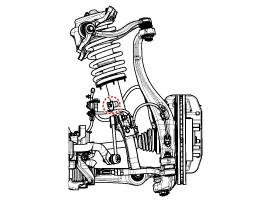

Loosen the bolt & nut (A), separate the front shock absorber assembly from the lower arm.

[4WD]

[2WD]

|

| 5. |

Disconnect the connector and loosen the wheel speed sensor bracket bolt to remove it. [ECS]

|

| 6. |

Loosen the wheel speed sensor bracket bolt to remove it. [HPD]

|

| 7. |

Remove the split pin & castle nut.

|

| 8. |

Disconnect the front upper arm from the knuckle using a SST (09568-2J100).

|

| 9. |

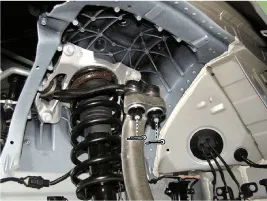

Disconnect the front strut assembly from the frame by loosening the mounting bolt (A).

|

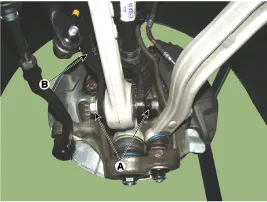

| 10. |

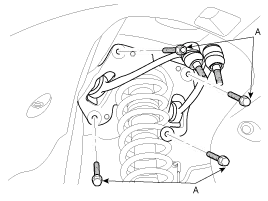

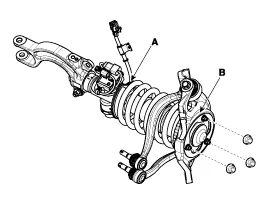

Loosen the nuts and remove the bracket (B) from the strut assembly (A).

|

| 11. |

Install in the reverse order of removal. |

| 12. |

Check the alignment.

(Refer to Tires/Wheels - "Alignment")

|

| Disassembly |

| 1. |

Compress the coil spring with a strut spring compressor. Do not compress the spring excessively. |

| 2. |

Remove the lock nut (B) after removing the cover (A).

|

| 3. |

Gradually turn the bolt on the spring compressor to slowly

release the tension from the spring. Then, disconnect the components. |

| 4. |

Reassembly is in the reverse order of disassembly.

|